Chaep 2016 5:1 general type room temperature epoxy potting adhesive

This product is non-dangerous goods and is transported and saved according to general chemicals.

shelf life is 12 months under 25 ℃. Please take a sample test before storage.

Black and white adhesive, in the stored procedure will have settlement, is normal phenomenon, can be inverted on a regular basis, can reduce settlement.

Normal temperature can be cured, the curing process is low temperature,

low shrinkage rate.

Solid surface light, not cracking, moisture proof, insulation

Color: Black, White

Packging: 5kg/barrel, 25kg/barrel

Application:

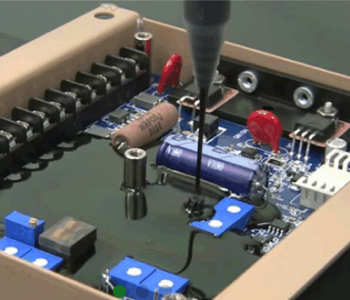

Used for general electronic components filling and sealing of circuit boards.

Normal temperature can be cured, the curing process is low temperature, low shrinkage rate. Solid surface light, not cracking, moisture proof, insulation

Use:

After stirring thoroughly in the original packaging (no need stirring without filler),Mix part A and part B by mass ratio(See the table above for mixing ratios), Stir well and then potting.See the table above for the available time after mixing.Over time, the glue viscosity will be high and it is no longer suitable for perfusion.Therefore, the amount of glue should not be too much each time, otherwise it will cause waste.

Curing: Curing conditions see above table. The curing speed is related to the temperature, the temperature is high and curing is fast, the winter temperature is low, the curing time is prolonged, and various glues can be heated and cured.Curing for 2 to 3 hours at 80° After the glue is hardened, it can be assembled. The test generally needs to be cured after 24 ~ 48 hours.

Operation process:

PartA will settle in the storage process, first mix Part A in the original package, and then add Part A and Part B components by a weight ratio of 5:1. Potting.

component may crystallize or agglomerate (normal condition) during storage.If crystallized, need to be placed in an oven at 80°C to melt before use(the container should be open to avoid gas expansion and damage the container), and then used after being cooled to room temperature, this does not affect its performance.

It is normal for different seasons to have different curing speeds due to temperature changes, and low curing temperatures in winter will be slower. All the above glues can be heated and cured.

Item | 2016 |

Mixing ratio, weight ratio | 5:1 |

Initial time, hr,25℃ | 4~6 |

Full cure time,hr, 25℃ | 24 |

Hardness,Shore-D | >80 | |

Volume resistivity,Ω.cm,25℃ | 1.0×1014 | |

Breakdown voltage,kV/mm,25℃ | >18 | |

Dielectric constant,1.2MHz,25℃ | 3.1±0.1 | |

Dielectric loss tangent,1.2MHz | <0.01 | |

Curing shrinkage,% | <2 | |

Thermal conductivity,W/K.T | 0.35 | |

Shear strength,Fe-Fe,MPa | >7 | |

Operating temperature range,℃ | -40~120 | |

Chaep 3116 High-temperature 100:8 solventless, room temperature curing epoxy potting material

A two-component solventless, room temperature curing epoxy potting material for automotive, automotive electronics, power tools, reactors, instruments with high thermal conductivity requirements of the product package protection, and has excellent adhesion and heat resistance.

Heat curing will bring high heatresistance

Excellent adhesion, anti-cracking

Low CTE linear expansioncoefficient

Having a high thermalconductivity

Excellent electrical insulation,stability

Long-term use at 150 ℃ -180℃

Very low water absorption, good waterproof, moistureresistance

Color: Black, Clear

Packging: 10kg/barrel, 0.8kg/barrel

Application: Uesd for automotive, automotive electronics, power tools, reactors, instruments with high thermal conductivity requirements of the product package protection

Operation process:

Preparation: Put A material original packaging barrels at 40 ℃ environment preservation 2 hours, after take out, compound viscosity is thinning,

Or use directly at normal room

Mixing:Withthe A component of the filler will contain the time to precipitate down, so use a stirrer to make the filler and resin liquid mixed evenly. Then weighing A / B components with Ratio 100:8, mixing thoroughly for several minutes. After, the finished liquid will be ready for

ComponentB may occur during storage or agglomeration of crystal (a normal case), if required before use crystalline placed in an oven at 60 ℃ to melt it, and then cooled to room temperature and after use, which does not affect its

The exposed component B will be hydrolyzed in moisture and the color of hydrolysate will show the color of white as friable

Good potting device, if necessary, vacuum may continue to help increase the electrical properties of the product

Before cured | Item | Method | Unit | CHAEP 3116 A | CHAEP 3116 B |

Appearance | Visual inspection | — | Black Liquid | Beige paste | |

Viscosity | GB/T 10247-2008 | 25℃,mPa·s | 20,000±3,000 | 25 | |

Density | GB/T 13354-92 | 25℃,g/cm3 | 2.35±0.05 | 0.93±0.05 | |

Mix rate | Mass ratio | Ratio=A:B | 100 :8 | ||

Mix viscosity | GB/T 10247-2008 | 25℃,mPa·s | 2,000±300 | ||

Operation time | GB/T 10247-2008 | 25℃,min | 45 | ||

Gel time | GB/T 10247-2008 | 60℃,min | 60 | ||

After cured | Hardness | GB/T 531.1-2008 | Shore D | 90 | |

Thermal conductivity | GB/T 10297-1998 | W/mK | 1.0 | ||

linear thermal expansion coefficient | GB/T 20673-2006 | μm/(m,℃) | 20 | ||

glass transition temperature | DSC | ℃ | 95 | ||

Shear strength | GB 6328-86 | Mpa,Fe-Fe | ≥8 | ||

Shear strength | GB 6328-86 | Mpa,Al-Al | ≥8 | ||

Dielectric strength | GB/T 1693-2007 | kV/mm(25℃) | ≥18 | ||

Loss factor | GB/T 1693-2007 | (1MHz)(25℃) | 0.09 | ||

Dielectric constant | GB/T 1693-2007 | (1MHz)(25℃) | 2.9 | ||

Volume resistance | GB/T 1692-92 | DC500V,Ω· cm | 1.00E +15 | ||

Applying temperature | GBT 20028-2005 | ℃ | -50–180 | ||

Chaep 8116 two part clear transparent epoxy adhesive for bonding plastic parts and metals

Chaep 8116 transparent epoxy adhesive is a kind of epoxy resin adhesive with fast curing speed. This two-component epoxy adhesive is designed to bond ceramic, metal, glass, plastic, rubber, paper, cloth and other products.

Chaep 8116 transparent epoxy adhesive cures without heating. After thoroughly mixing the A component and the B component in a ratio of 3:1 (weight ratio or volume ratio), the product has a long operation time of 2 hours, good foaming property, and a transparent hard protective layer after curing.

Resists moisture, dirt and other atmospheric components

High strength, excellent adhesion

Good anti-pollution and low surface pretreatment requirements

Solvent free, no cure by-product

Stable mechanical and electrical performance between -50 and 120 °C

Good adhesion to plastic PC, fiberglass cloth and steel plate

Color: Black

Packging: 5kg/barrel, 1kg/barrel

Application: This two-component epoxy adhesive is designed to bond ceramic, metal, glass, plastic, rubber, paper, cloth and other products.

Use:

Items | Unit or condition | Chaep 8116 A/B |

Mix ratio | Weight ratio | 3 : 1 |

Mix ratio | Volume ratio | 3 : 1 |

Mix viscosity | mPa·s(25℃) | 300-600 |

Mix Density | g/cm3(25℃) | 1.10 |

Operation time (1) | min(25℃) | 120-150 |

Dead time | min(25℃) | 150-180 |

Initial cure time | 25℃/hr | 24 |

Operational precautions

Manual use of bulk packaging, it needs to be weighed and stirred quickly when mixing the glue, thismethod is suitable for places where the bubble requirements are not high; otherwise, it is necessary to use a two-component dispenser to mix and apply glue.

If the temperature is too low, the curing speed will be too slow. When the initial strength cannot be reached, the constant temperature control on site is needed.

The curing process of the glue is an exothermic reaction, and the amount of the glue will affect the length of the operation time. Therefore, the operation time under the glue amount of 60g is only a reference time.

Conventional performance

Test items | Test standard | Unit | Chaep 8116 A/B | |

| Part A | Appearance | Visual | — | Transparent thick liquid |

Viscosity | GB/10247-2008 | mPa·s(25℃) | 10000-13000 | |

Density | GB/T 13354-92 | g/cm3(25℃) | 1.10 | |

| Part B | Appearance | Visual | — | Transparent liquid |

Viscosity | GB/10247-2008 | mPa·s(25℃) | 10-50 | |

Density | GB/T 13354-92 | g/cm3(25℃) | 1.10 | |

Typical performance

Items | Test standard | Unit | Chaep 8116A/B |

hardness | GB/T 531.1-2008 | Shore D | 82 |

Shear strength | GB 6328-86 | Mpa,Al/Al | 15 |

Shear strength | GB 6328-86 | Mpa,PC/ PC | 10 |

Expansion coefficient | GB/T 20673-2006 | μm/(m,℃) | 44 |

Bibulous rate | GB/T 8810-2005 | 24h,25℃,% | <0.3 |

Dielectric strength | GB/T 1693-2007 | kV/mm(25℃) | >20 |

Dissipation factor | GB/T 1693-2007 | (1MHz)(25℃) | 0.014 |

Dielectric constant | GB/T 1693-2007 | (1MHz)(25℃) | 3.53 |

volume resistance | GB/T 1692-92 | (DC500V)Ω· cm | 1.2×1015 |

Chaep 6026 Transparent two-component epoxy structural adhesive

Two-component solventless epoxy structural adhesives with low viscosity, high hardness, excellent chemical resistance and mechanical properties.

Excellent adhesion and cracking resistance

Excellent electrical insulation and stability

Very low water absorption, good waterproof, moisture-proof

Color: Clear

Packging: 20kg/barrel, 20kg/barrel

Application: Widely used in automotive electronics, pressure sensors, connecting harnesses, motor magnetic sheet bonding.

Use:

Matching glue: The components A and B are weighed and weighed according to the weight ratio of 5:2. After mixing, the potting can be carried out.

The operation time of this product is short. If the amount of glue is large, it is recommended to take multiple mixing.

The potted device can continue to be vacuumed if necessary, which is beneficial to increase the electrical performance of the device.

Curing conditions: 80 ° C / 2 h or 25 ° C / 24 h hours. If you need to use glue filling equipment, please consult our marketing department.

| Before curing | Item | Test method | Unit | CHAEP 6026 A | CHAEP 6026 B |

| Color | Visual | — | transparent liquid | Light yellow transparent liquid | |

| Viscosity | GB/T 10247-2008 | 25℃,mPa·s | 5,000±800 | 60±10 | |

| density | GB/T 13354-92 | 25℃,g/cm3 | 1.14±0.05 | 1.00±0.05 | |

| Mixing ratio | Mass ratio | Ratio=A:B | 5 : 2 | ||

| Mixed viscosity | GB/T 10247-2008 | 25℃,mPa·s | 600±100 | ||

| Operating time | GB/T 10247-2008 | 25℃,min/120g | 25 | ||

| Initial curing time | GB/T 10247-2008 | 25℃,min/120g | 120 | ||

Chaep 2126 two component epoxy structural adhesive for metal bonding, aluminum honeycomb panel

Chaep 2126epoxy adhesive can be cured at room temperature and in a heated environment. After mixing the A and B components at a mass ratio of 2:1, the product is cured within a certain period of time to form a protection.

Solvent free, no cure by-product

Good toughness

Excellent adhesion, high and low temperature impact resistance

Good waterproof and moisture resistance, low water absorption

Color: Black, White

Packging: 20kg/barrel, 20kg/barrel

Application: Used for metal bonding, aluminum honeycomb panel splicing and motor core Nomex bonding with excellent adhesion and toughness.

Use:

Surface treatment: For surface treatment, use a solvent such as methyl ethyl ketone/isopropanol to wipe the surface of the substrate to be bonded, or use sandpaper for sanding.

Glue mixing: it is recommended to mix component A and component B well before use, and then weigh and mix them according to the weight ratio of 100:50. Component A and component B should be sealed and stored after use.

The glue material at the bottom and the border of the container should also be mixed evenly during stirring, otherwise the local non-solidification phenomenon caused by uneven stirring may occur. After uniform stirring and vacuum defoaming, it is ready for use. Please use up as soon as possible.

Low ambient temperature will lead to slow curing speed, when the initial strength cannot be achieved, the need for constant temperature control in the field.

If dual syringe type duo-pak plastic box is used (twin tube), exclusive glue gun is needed. Please note that glue is made in the assembly of new mixed tube, a small part at the beginning should be discarded until a uniform color, continuous and even glue flow is obtained, and then it can be used normally.

The curing process of this glue is exothermic reaction, and the amount of glue will affect the length of operation time, so the operation time under the amount of glue 10g is only a reference time.

Meet the basic curing conditions of performance testing, 24 or 25 ℃ 80 ℃ * 2 hours * d.

If you need to use automatic dispensing and sizing equipment, please consult our Marketing Department.

| Color | Visual | Black paste | Rice white paste | |

| Viscosity 25 ° C, mPa·s | GB/T 10247-2008 | 30,000-40,000 | 100,000-120,000 | |

| Density 25 ° C, g / cm3 | GB/T 13354-1992 | 1.43±0.05 | 1.35±0.05 | |

| Mixing ratio Ratio=A:B | Mass ratio | 100 : 50 | ||

| Operating time after mixing, 25 ° C, 10 g | GB/T 10247-2008 | 20mins | ||

| Initial curing time 25 ° C, 10 g | GB/T 10247-2008 | 4-5 hrs | ||

| After curing | Hardness Shore D, 25°C | GB/T 531.1-2008 | 63 | |

| Shear strength Mpa, iron/iron | GB 6328-1986 | ≥18 | ||

| Shear strength Mpa, aluminum / aluminum | GB 6328-1986 | ≥15 | ||

| T-type peel strength N/mm | GB/T2791-1995 | 6 | ||

| Elongation at break,% | GB/T 528-2009 | 70 | ||

| Thermal conductivity W/K.m | GB/T 10297-1998 | 0.35 | ||

| Operating temperature °C | GBT 20028-2005 | -40–150 | ||

Chaep 1096 two-component temperature resistant epoxy potting compound

Two-component solvent-free, heat-curing epoxy potting compound with a long gel time at room temperature. It is specially developed for long-term high temperature resistance of 250℃.

Excellent adhesion, crack resistance

Good toughness and high hardness

Excellent electrical insulation and stability

Very low expansion coefficient

Higher Tg point, heat resistant S grade, can be used at 180 °C for a long time

Good waterproof and moisture resistance, low water absorption

Color: Black, White, Brown

Packging: 24kg/barrel, 1kg/barrel

Application: It can be applied to sensors, high temperature wire harnesses, automotive electronics. Package protection for products with higher temperature resistance, excellent adhesion and low shrinkage.

Use:

Glue mixing: mix component A and component B in the original package evenly, then weigh and mix them according to the weight ratio of 3:1, mix them evenly and then seal them.

If you need the viscosity of mixed rubber is low, recommendations will be A preliminary drying under 80 ℃, then mix B material, mix viscosity within 2000 CPS.

Part B crystallization may occur during storage or agglomerate (normal), if the crystal should be put it at 80 ℃ oven before using the melting (container should be in the open state, in order to avoid gas expansion, damaged container), and then cooling to room temperature after use, it doesn’t affect its performance.

If necessary, vacuum can be continuously pumped to increase the electrical performance of the device.

Curing conditions: 120 ℃ for 1 hour.

Please consult our Marketing Department if you need to use the filling equipment.

Item | Test method | CHAEP 1096 A | CHAEP 1096 B |

Composition | Visual | White/black liquid | Brown liquid |

Color | GB/T 10247-2008 | 220,000 | 100 |

Viscosity 25 ° C, mPa·s | GB/T 13354-92 | 1.68±0.05 | 1.05±0.05 |

Density 25 ° C, g / cm3 | Mass ratio | 3 : 1 | |

Mix viscosity 25 ℃, Pa, s | GB/T 10247-2008 | 6,500 | |

Operating time 25 ℃, mins | GB/T 10247-2008 | 500 | |

Gel time of 25 ℃, hr | GB/T 10247-2008 | 16 | |

Curing time of 120 ℃, hr | GB/T 10247-2008 | 1—2 | |

Hardness Shore D | GB/T 531.1-2008 | 91 | |

Thermal conductivity W/mK | GB/T 10297-1998 | 0.35 | |

Chaep 3096 two part thermal conductivity epoxy potting adhesive

Two-part solvent free heat curing epoxy potting compound. Room temperature curing will take a long time. Specially designed for the special requirements of long-term high temperature up to 260°C.

Good adhesion and anti-crack property

Good toughness and high hardness

Good waterproof, moisture resistance, very low water absorption

Excellent electrical insulating properties, stability

Very low expansion coefficient

Very high glass transition temperature, can be used in 260°Cfor a long time

Color: Black, White, Clear

Packging: 5kg/barrel, 1kg/barrel

Application: Encapsulating for electronics which need high temperature resistant requirements, such as sensors, high temperature wire harness, automotive electronics etc.

Use:

Stir part A in origin container in advance, then mix partA and part B by weight ratio 5:1 evenly, vacuum to remove bubbles, casting and filling during the operation period.

It's a normal phenomenon of crystallization or agglomeration during the storage of part B, should thaw it by putting it into an 80°C

(To avoid gas expansion and destroy container, the container should be opened.)

And then cooled to room temperature to use, this does not affect its performance.

If necessary, continue to vacuum defoaming for components which been potted, help to increase the electrical performance of the device.

Curing condition: heat curing in temperature 1hr/120℃+1hr/150℃.

Item | Unit | CHAEP 3096A | CHAEP 3096B |

Composition | — | White/black paste | Transparent liquid |

Color | 25℃,mPa·s | 150,000±30,000 | 100±10 |

Viscosity | 25℃,g/cm3 | 1.71±0.05 | 1.16±0.05 |

Mixing ratio | Ratio=A:B | 5:1 | |

Operating time | 25℃,hr | 10 | |

Gel time | 25℃,hr | 16 | |

Curing time | hr | 1hr/120℃+1hr/150℃ | |

Thermal Conductivity | W/m.k | 0.65 | |

Glass transition temperature | ℃ | 190 | |

Thermal Conductivity | DC500V,Ω· cm | 2.00E +15 | |