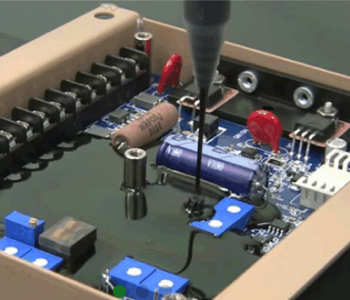

Chaecoat 1609 Low viscosity solventless silicone conformal coating

A low viscosity neutral conform coating silicone. solid content is 100%. Easy to spray, dip, brush or apply. Protective coating for hard and soft printed circuit boards and Protective coating of impregnated porous substrate.

One-part, low-viscosity, solvent-free, environmentally friendly

High transparency, room temperature curing, good adhesion

After curing, it is stable and elastic at -60 – 200°C

good adhesion with most base material without primer

Excellent waterproof, anti-corrosion, moisture, electrical insulation

Color: Clear

Packaging: 1L/barrel

Application: Suitable for coating with thick film circuit and printed circuit board; seal LCM LCD border; Other applications requiring good permeability

Use:

Cleaning surface: cleansurface, remove rust, dust and oil.No need bottom coating to most material, such as glass, metal and most commonly industrial plastics.But on some polymers, it may be less cohesive.For example: polyethylene, polypropylene and PTFE, use PM1200 to do bottom coating.

cut the nozzle to the required size, Fitted with glue gun, squeeze the glue into the cleaned surface and distribute evenly, When bonding, fixed two surface together. Under the conditions of room temperature and 55% relative humidity, adhesive’s surface dry in about 15 minutes, therefore, all processing must be completed before surface dry.

Cured:Cured: place the coated parts in the air and used them after curing for 24 hours at room temperature.

Precautions: after opening Becoat 921, use it as soon as possible, once again, when used again, squeeze out the solidified part, continue to use, do not affect normal use.

please consult the market departmentif use dispensing equipment.

| Item | Test standard | Unit | 0009 | 1609 |

| Properties before curing | ||||

| Color | Visual | — | Clear | |

| Viscosity | GB/T 10247-2008 | 25℃, Pa·s | 3000±500 | 1000±300 |

| Density | GB/T 15223-1994 | 25℃, g/cm3 | 1.00±0.02 | |

| Tack free time | GB/T13477-2002 | 25℃, 55%RH,min | 7-10 | 5-7 |

| Solid content | GB18583-2008 | % | 100 | |

| Properties after curing | ||||

| Hardness | GB/T 531-2008 | Shore A | 20 | |

Chacoat 7609 Low viscosity Solvent type silicone conformal coating

7609 is a one-component, solvent type conformal coating ,based on silicone. It cures on exposure by moisture to form an elastic silicone rubber

7609 has excellent corrosion-free adhesion to metals, including copper, plastics, ceramics, glass, etc, without the use of

Excellent high and low temperature resistance: from –60℃to250℃.

Stably under working temperature 200? for longterm

Excellent weather ability, water and chemicalresistance

Excellent electrical insulation

Simple and easy-to-use one-component

Color: Clear

Packaging: 1L/barrel

Application: Suitable for coating with household control module; Impregnated transformers; Inductive protection; Tough and flexible PCB coating;LED lights’ surface coating

Use:

Clean the surface thoroughly, keep dry and loose debrisoClean with a solvent.

Spraying with a dispenser. Thinner dosage recommendations for 30~50%. Diluent recommends the use of toluene and petroleum ether, do not use solvent such as alcohols, ketones.

Dip-coating process. dip the PCB into the glue, and stay for about 10seconds to avoid bubbles.

How to apply

Apply a bead of Becoat 9067 Adhesive/Sealant (see Handling Precautions) to one of the prepared surfaces.

On exposure to moisture, the freshly applied material will “skin-over” in about 20-30 minutes at room temperature and 50% relative humidity. Any tooling should be completed before this skin forms. The surface is easily tooled with a spatula. The adhesive/sealant will be tack-free in approximately 30 minutes.

Cure time

In 24 hours (at room temperature and 50% relative humidity) Becoat 9067 Adhesive/Sealant will cure to a depth of about 2-3mm. If deeper sections, especially when access to atmospheric moisture is restricted, will take longer to cure completely.

Cure time is extended at lower humidity levels. Before handling and packaging bonded components, users are advised to wait a sufficiently long time to ensure that the integrity of the adhesive seal is not affected. This will depend on many factors and should be determined by the user for each specific application.

To reach stable property, it’s better to rise the temperature step by step, for example, after cured 7 days, heat the sealant on 150℃ for 5 hours, then 200℃ for 4hours, 230℃ for 4hours, 250℃ for 3 hours ,and 280℃ for 2hours.

TYPICAL UNCURED PROPERTIES | |

7609 | |

Appearance | COLOR |

Solid content | 70% |

Specific GravityCg/cm33, GB/T 15223-1994 | 0.95±0.05 |

25ŠTack-free Time(min), GB/T13477-2002 | 25±5 |

TYPICAL CURED PROPERTIES (7 DAYS @ 25?/55%RH) | |

Hardness, Shore A, GB/T 531-2008 | 20 |

Tensile strength (Mpa), GB/T 528-2009 | >0.6 |

Chasil 2009 one-component fast skin-curing flowable silicones sealant

2009 is a one-component, fast skin-curing, non-corrosive silicone adhesive sealant that cures on exposure bymoisture to form an elastic silicone rubber.

In between -60-260 ℃ stable mechanical and electrical properties

Excellent outdoor aging, the service life of up to 20-30 years

Room-temperature curing;

Resist humidity and other harsh environments;

good dielectric properties;

self-priming adhesion;

low viscosity, flowable;

High transparency and high physical and mechanical properties

Color: Clear

Packaging: 310ml

Application: LED lamps sealed, Plastic metal shell sealing, PCB board components, Wiring harness fixed, Electronic

Use:

Apply a bead of 2009 Adhesive/Sealant (see Handling Precautions) to one of the prepared surfaces, then quickly cover with the other substrate to be bonded.

On exposure to moisture, the freshly applied material will “skin-over” in about 3-5 minutes at room temperature and 50% relative humidity. Any tooling should be completed before this skin forms. The surface is easily tooled with a spatula. The adhesive/sealant will be tack-free in approximately 10 minutes.

| Items | Method | Unit | Value |

| Before cured | |||

| Color | Visual inspection | — | transparent |

| Viscosity(cp) | GB/T 2794-2013 | 25℃, mPa·s | 30,000 ± 10,000 |

| Specific Gravity | GB/T 15223-1994 | 25℃, g/cm3 | 1.02±0.02 |

| Tack-free | GB/T13477.5-2002 | 25℃, 55%RH,min | 20 |

| After cured | |||

| Hardness | GB/T 531-2008 | Shore A | 28 ± 3 |