CHAGR 2111 5111 0211 5211 5311 Thermal conductivity silicon grease

Thermal conductive silicon grease is used in electronic devices for thermal conductivity materials, with excellent thermal conductivity.

Thermal conductivity: 1.2-3.5 W/m.K

Low settling, room temperature storage

Excellent resistance to high and low temperature, excellent weather and radiation resistance

Excellent dielectric properties

Excellent chemical and mechanical stability

Color: White

Packaging: 1L/barrel

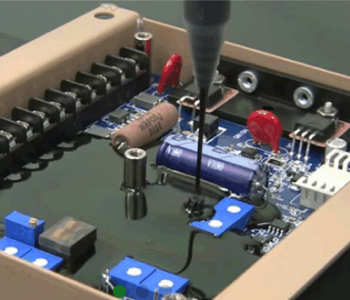

Application: Power module, Integrated chip, Power supply module, Automotive electronics, The telecommunications equipment, Com, puter and its accessories

CHAGR 11 seriescan be applied by hand, specially designed automated equipment, brushing or wiping. Certain designs of grease guns may seize up with silicone compounds; test prior to use. A thinner consistency can be achieved by dispersing in solvents such as xylene, mineral spirits and methyl ethyl ketone.

CHAGR 11 seriescan then be applied by brushing, dipping or spraying. CHAGR 11 series should not be applied to any surface which will be painted or finished.

Such coatings may not adhere to the silicone-treated surface. If contaminated by a silicone coating, parts can be wiped or washed with solvent, washed with detergent, or immersed in an alcoholic potassium hydroxide solution and then rinsed in clear water before

| Item | Test Methods | CHAGR 2111 | CHAGR 5111 | CHAGR 0211 | CHAGR 5211 | CHAGR 5311 |

| Base material | ASTM D374 | silicone | silicone | silicone | silicone | silicone |

| Appearance | Visual | White liquid | White liquid | White liquid | White liquid | White liquid |

| Viscosity mPa.s | G B/T2794-2013 | 120,000 | 80,000 | 200,000 | 150,000 | 250,000 |

| Thermal conductivity (W/m∙K) | ASTM D5470 | 1.2 | 1.5 | 2.0 | 2.5 | 3.5 |

| Density (g/ cm3) | ASTM D792 | 2.1 | 2.3 | 2.7 | 2.8 | 3.0 |

| Volatile (%) | <1 | <1 | <1 | <1 | <1 | |

| Oil from (%) | <2 | <2 | <2 | <2 | <2 | |

| Dielectric constant (MHz) | ASTM D150 | 3.4 | 3.4 | 4.0 | 4.4 | 4.0 |

| Volume resistance(Ω·cm) | ASTM D257 | ≥2×1014 | ≥2×1014 | ≥2×1014 | ≥2×1013 | ≥2×1012 |

| Long-term use temperature range, ℃ | -60 to +250°C | -60 to +250°C | -60 to +250°C | -60 to +250°C | -60 to +250°C |

CHAGR 092 392 592 silicone oil base transparent silicone grease lubrication

An efficient silicone oil base, transparent silicone grease lubrication, specially used in dielectric isolation, surface protection, demolding and lubricating, etc. applications.

Color: White

Packaging: 20kg/barrel

Application:

Isolation protection

Water and moisture proof(Ignition systems, insulated switch, transformers, power equipment, cables, etc.)

As agingretarder for plastic and rubber

As surface protective agent for metals (Ignition system, TV anode cap, battery terminals, cables and connectors, etc.)

Good adhesionof machine and seal ring

Sealing and crack pouring in electronics

Use:

Apply with grease gun, daubing or using brush. Can be used through spraying or soaking when the concentration is 10%

| Item | Unit | 092 | 392 | 592 |

| Color | White, translucent | White, translucent | White, translucent | |

| Penetration unworked, | 1/mm | 200 | 195±10 | 310 |

| Penetration worked 60, max, | 1/mm | 210Max | 210 Max | 340Max |

| Bleed, 30hours/200°C,max | % | 0.20Max | 0.2% Max | 0.05Max |

| Evaporation, 30 hours/ 200°C, max | % | 0.95Max | 0.95% Max | 1.15Max |

| Service temperature range¹ | °C | -55 to +200 | -55 to +200 | -55 to +200 |

| Relative density at 25°C | g/cm3 | 1.0 | 1.0 | 1.0 |

| Dielectric strength, 1.27mm gap | kV/mm | 18 | 18 | 18 |

| Permittivity at 100Hz | 2.90 | 2.90 | 2.90 | |

| Permittivity at 1000kHz | 2.90 | 2.90 | 2.92 | |

| Dissipation factor at 100Hz | 0.002 | 0.002 | 0.002 | |

| Dissipation factor at 1000kHz | hm.cm | <0.002 | <0.002 | <0.002 |

| Volume resistivity at 23°C o | hm.cm | 0.2 x 10¹5 | 0.2 x 10¹5 | 0.2 x 10¹5 |

| Arc resistance | seconds | 120 | 120 | 120 |