Technical Data

PROPERTYPU310 | PU120A | PU120B |

Appearance | Black/White/Grey Paste | Black/White/Grey Paste |

Density (g/cm³) | 1.35±0.5 | 1.35±0.5 |

Tack Free Time (Min) | ≤180 | ≤180 |

Elongation at break | ≥600 | ≥500 |

Hardness (Shore A) | 30±5 | 35±5 |

Extrusion rate (ml/min) | ≥60 | ≥50 |

Curing Speed (mm/24h) | 3 ~ 5 | 3 ~ 5 |

Tensile modulus | ≤0.4

| ≥0.4 |

Volatile content | ≥95 | ≥95 |

Operation Temperature ( ℃) | 5-35 ℃ | 5-35 ℃ |

Service Temperature ( ℃) | -40~+80 ℃ | -40~+80 ℃ |

Shelf Life (Month) | 9 | 9 |

Storage Notice

1. Sealed and stored in cool and dry place.

2. It is suggested to be stored at 5~25 ℃, and the humidity is less than 50%RH.

3. If the temperature is higher than 40 ℃ or the humidity is more than 80%RH, the shelf life may be shorter.

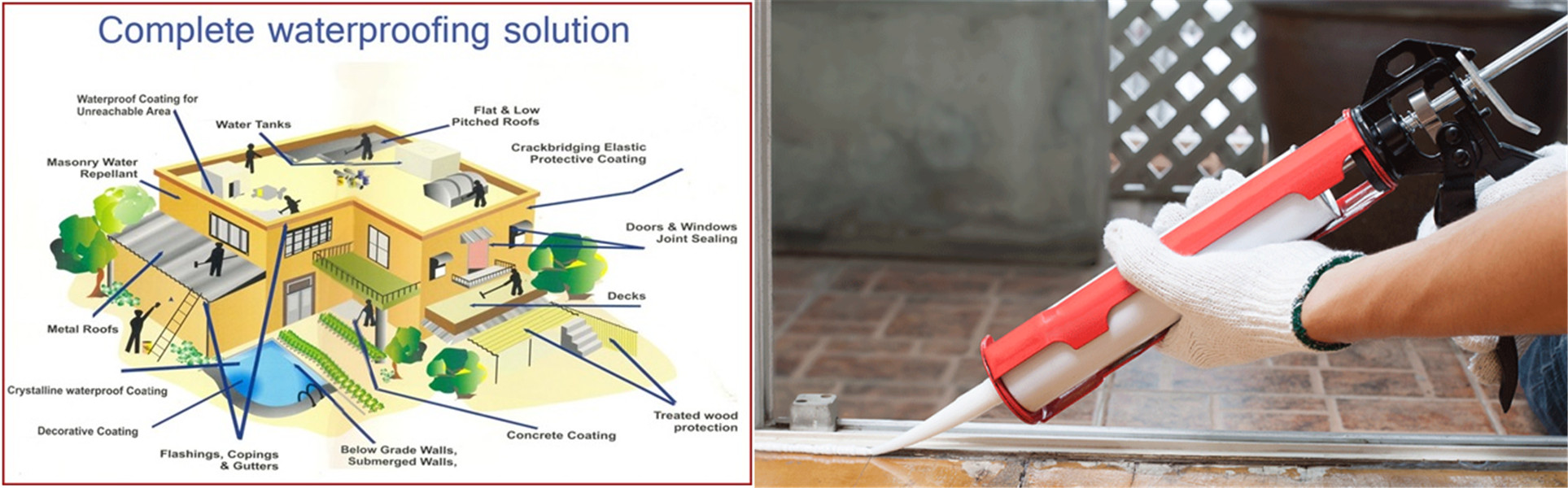

Applications

1. Sealing of expansion and settlement joint of house building, plaza, road, airport runway, anti-wall, bridges and tunnels, building doors and windows etc.

2. Sealing of upstream face crack of drainage pipeline, drains, reservoirs, sewage pipes, tanks, silos etc.

3. Sealing of through holes on various wall and at floor concrete

4. Sealing of joints of prefab, side fascia, stone and color steel plate, epoxy floor etc.

5. Water-proof sealing in Airport runway, bridge and tunnel joints, drainage pipe, etc.

6. Bonding and sealing of concrete prefab, side fascia, stone and color steel plate.

7. Bonding and sealing of dale such as metal plates, wood board, plaster tablet and so on.

8. Excellent bonding, sealing and repairing of various kinds of materials, such as concrete building, wood, metal, PVC, ceramics, carbon fiber, glass, etc.

Operation

Cleaning

1. The substrate surface must be solid, dry and be clean.

2. Keep the surface free of dust, grease, asphalt, tar, paint,wax,rust,water, curing agent,old sealants and any protective coating.

Tool: Manual or pneumatic plunger caulking gun

For cartridge

1. Cut nozzle to give the required angle and bead size

2. Pierce the membrane at the top of the cartridge and screw on the nozzle

3. Place the cartridge in an applicator gun and squeeze the trigger with equal strength

For sausage

1. Clip the end of the sausage and place in barrel gun

2. Screw end cap and nozzle on to barrel gun

3. Using the trigger extrude the sealant with equal strength

Attention

1. The tools with the alcohol can’t be used before cleaning well.

2.Avoid contact with eyes and skin.

3. If contact with your skin, scrub first with soap water or alcohol, then rinse with water.

4. If contact with your eyes, rinse with plenty of water, and seek medical treatment immediately.

5. It is forbidden to build on the surface of the wet substrate.

6. Transportation: Avoid damp, high temperature,isolation and rain, far away from heat, handle with care and prohibit extrusion collision.

7. Tools Cleaning : It can be soaked in toluene or xylene. It is strictly forbidden to immerse in alcohol and other alcohol solvents.If it is not used for a long time, it should be cleaned immediately with alcohol or other organic solvents. The cured glue can only be scraped or torn off.

Package

1. 310ml cartridge, 400ml/600ml sausage, 20pcs/box, 2 boxes/carton.