Main Property

1. The emulsion is an excellent Polyurethane Material with excellent elastic waterproof performance.

2. Mainly be used as waterproof coating material, sealing glue, etc.

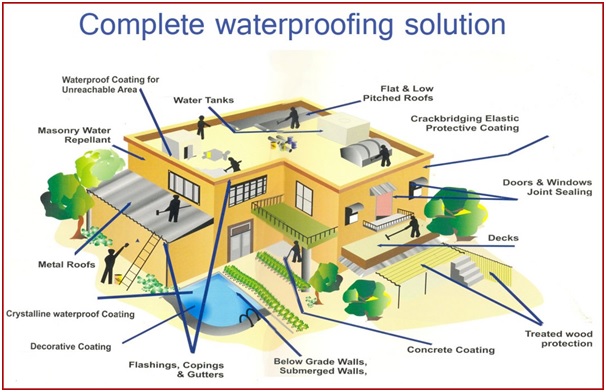

Applications

Planar Bonding and Sealing:

1. Excellent bonding, sealing and repairing of various kinds of materials, such as concrete building, wood, metal, PVC, ceramics, carbon fiber, glass, etc.

Planar Waterproofing:

1. Waterproofing and moisture proofing for kitchen, bathroom, balcony,roof and so on.

2. Anti-seepage of reservoir, water tower, water tank, swimming pool, bath,fountain pool, sewage treatment pool and drainage irrigation channel.

3. Leak-proofing and anti-corrosion for ventilated basement, underground tunnel, deep well and underground pipe and so on.

4. Bonding and moisture proofing of all kinds of tiles, marble, wood,asbestos and so on.

Technical Data

PROPERTY | STANDARD/UNITS | VALUE |

Color/state | Liquid | Black/White |

Density | Gr/cc | 1.30±0.5 |

Surface Drying time | Hr | 6-8 |

Curing speed | mm/ 24hrs | 3~5 |

Tensile Strength | MPa | >1.5 |

Elongation at break | % | >800 |

Solid Content | % | >90 |

Operation Temperature | °C | 5-35°C |

Service Temperature | °C | -40~+120°C |

Shelf life | month | 9 |

Note:The above data are obtained by testing the material after curing for 7 days under certain conditions

Operation Guidance

1. As waterproof coating, the best thickness is no more than 2mm to prevent the bubbles.

2. It can not be exposed, a proper protective layer need be operated on the surface of the coating.

3. Environmental requirements:The temperature is 5~35 C and the humidity is 35 ~ 85%RH.

4. Cleaning:The substrate surface must be solid, dry and be clean. Such as no dust, grease, asphalt, tar, paint, wax, rust, water repellent, curing agent, isolating agent and film. Surface cleaning can be dealt with by removing, cleaning, blowing, and so on.

5. Make the substrate surface level:If there are cracks on the substrate surface,first step is to fill them, and the surface should be leveled. Operation after the sealant curing more than 3mm.

6. Theoretical dosage: 1MM thickness requires 1.3 kilograms of material per square meter.

Attention

1. Don’t mix alcohol into the product, it will cause the product invalid. The tools with the alcohol can’t be used before cleaning well.

2. The total coating thickness is around 2.0mm as a advice, special parts can be more than 2.0mm.

3. Avoid water, pollution and damage before tack free time of the coating, prohibit any operation before full curing (about 24Hrs).

4. Ventilated environment is required as operating, and some necessary safety precautions should be taken. During operation, records should be filled in truthfully. For special projects, follow the construction description strictly.

5. Avoid contact with eyes and skin directly.Once in contact with your skin, scrub first with soap water or alcohol, then rinse with water. Once in contact with your eyes, rinse with plenty of water, and seek medical treatment immediately.

6. It is forbidden to operate on the surface of the wet substrate.

7. Transportation: Avoid damp, high temperature,isolation and rain, far away from heat, handle with care and prohibit extrusion collision.

Package & Storage

1. 1KG/Drum, 5Kg/Drum, 20KG/Drum, 25KG/Drum; 230Kg/Drum.

2. Sealed and stored in cool and dry place.

3. It is suggested to be stored at 5~25 ℃, and the humidity is less than 50%RH.

4. If the temperature is higher than 40 ℃ or the humidity is more than 80%RH, the shelf life may be shorter.