Chapu 0206 two-component flame retardant solvent-free Polyurethane potting material

Two-component solvent-free potting resin. It cures in room temperature or heating temperature. It’s using for electronics sealing, potting, flame resistant etc. The raw material does not contain heavy metal, it’s environmental with widely operability, high physical properties of the finished product, good adhesion with substrates. It can be deep cured, less heat release when curing, low shrinkage rate. Excellent flexibility after curing with flame retardant efficiency.

Excellent low temperature and weather resistance properties.

Excellent flame retardant efficiency

Excellent electrical insulation

Good waterproof, moisture resistance, very low water absorption

Good adhesion to almost metal and plastic.

Color: Light yellow fluid

Packaging: Part A: 18 kg/pail, Part B: 4 kg/pail

Application:

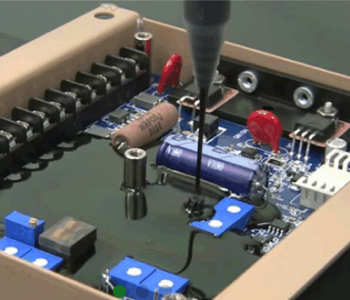

For electronic capacitor, automotive electronics models potting;

For household appliances PCB potting, such as lampblack cookers, microwave oven, electric cooker, washing machine, air-condition.

Moisture-proof and water-proof for PCB and magnetic induction loop of intelligent close stool, induction toilet, metal induction garbage can encapsulate and protection.

Use:

Preliminary drying: please dry PCB and substrates which need to potting in 50°C condition,then put it in application place.

Mixture: mixing A and B according to mass ratio, to reducemix air, should vertically stir as same direction about 2-3 minutes. The edge and bottom of container also should be stir well, otherwise, it will appear partial non solidified phenomenon. The entire operation process, A and B, mixer, stir tool etc. all should avoid getting to water and moisture. If working place has air-container, it will be better to keep constant temperature and humidity (T&H: 23°C,50%)

Defoaming: For demanding of smooth potting surface without bubbles, the mixed material should be defoamed under the vacuum pressure ≤-0.1mpa. It’s better to defoame by stirring along with vacuum together. (Suggest to use automatic mixing equipment, it not only can be mixed in proper precise proportion, and will not mix in air bubbles)

4.Potting: Pouring the mixed sealant into the devices,for complex structure or big size devices, should be poured by times. Can use a hot air gun to eliminate the surface floating bubbles.

Both A and B part should be sealed well, if it cannot be used up one time, please cover up bung again, sealed storage. Especially the part B, please try to reduce the time of contact with the air every time operating process.

Mix A and B evenly as mass ratio in a short time, the mixed resin should use up within operation time, or else it cannot be use.

The curing time is related to how many resin mixed and temperature, if the quantity is big and temperature is high, the curing time will be shorter; on the contrary, curing time will be longer.

Uncured resin is easy to clean, cured resin can use methylene dichloride cleaning, soaking,softening, stripping.

Curing: 25 °C/ (24) h, or 80 °C/60minutes, the humidity should below 50%, the curing time would be extended in a lower temperature.

For equipment operation,after dovacuum separately in the container of A and B, then measuring and mixing to pot into the devices, curing in airing or tunnel kiln.

| STANDARD/UNITS | VALUE of 0206 | |

Viscosity of mixture | 25°C, cps | 250±50 |

Operation time | 25°C, min | 15±3 |

Gel time | 25°C min, 100g | 20±4 |

Hardness | Shore-A | 23 |

Density | 25°C, g/cm3 | 1.06 ± 0.05 |

Application temperature | °C | -50~100 |

Thermal conductivity | W/m.K | 0.2 |

Chapu 0806 solvent-free two-component casting polyurethane encapsulant material

A solvent-free, two-component casting resin, based on Polyurethane. The resin (A) consists of organic compounds with hydroxyl-groups whereas the hardener (B) is based on isocyanates. By mixing both components in a ratio by weight, a flexible casting resin is achieved via chemical reaction. The product exhibits no measurable change in volume after curing.

Base: Polyurethane resin (PUR)

colorless, highly transparent and crystal-clear

very good weather resistance, outstanding UV light stability, good thermalresistance

operating temperature range -40 to at least +90 °C

very high optical transparency with low optical damping

very good adhesion to almost all materials

resistant against water, moisture, condensate and numerous chemicals, bases,acids and oils

Color: Clear

Packaging: Part A:20 kg/pail, Part B: 20 kg/pail

Application: used as a transparent casting material for lightning application. It shows high optical transparency, good weather and thermal resistance, and UV light stability.

| Type | Method | Unit | 0806 | |

| Component | A | B | ||

| Mix ratio | By weight | A:B | 1:1 | |

| Appearance | Clear colorless | Clear colorless | ||

| Viscosity | GB/T 10247-2008 | mPa·s | 1400±150 | 1200±150 |

| Gravity | GB/T 15223-1994 | g/cm3 | 1.05-1.15 | 1.11-1.21 |

| Pot life | GB/T 10247-2008 | 55%RH,min | 20-30 | |

| Curing time | GB/T 10247-2008 | 55%RH,hr | 12 | |

| Hardness | GB/T 531-2008 | Shore A | 80 | |

| Volume resistivity | GB/T 1692-92 | 25℃,Ω·cm | 1.4*1015 | |

| Water absorption | GB 8810-2005 | 24hrs, 25℃,% | <0.35 | |

| Working Temperature | GBT 20028-2005 | ℃ | -50–90 | |

Chapu X066 solvent-free 5:1 two-component casting resin Polyurethane potting material

A solvent-free, two-component casting resin, based on Polyurethane. The resin (A) consists of organic compounds with hydroxyl-groups whereas the hardener (B) is based on isocyanates. By mixing both components in a ratio by weight of 5:1 a flexible casting resin is achieved via chemical reaction. The product exhibits no measurable change in volume after curing.

medium viscosity, easilyprocess

excellent and stably electricaldielectric

very low Waterabsorption

good adhere to most metals andplastics

excellent performance on low-temperature andaging

Color: Black

Packaging:Part A-25kg/Bucket, Part B-5kg/Bucket

Application: It is specifically formulated for automotive sensors, switches, transformers and other electrical devises requiring environments protection.

Items | Chapu X066 A | Chapu X066 B |

Appearance | Black liquid | Brown liquid |

Viscosity, cps(25℃) | 600 ±100 | 40± 20 |

Gravity, g/cm3 | 0.98±0.03 | 1.15±0.05 |

Mixing ratio, by weight | A:B = 100 :75 | |

Mix viscosity, cps(25℃) | 350± 100 | |

Pot life, mins | 2 | |

Track free time, mins,25℃, 55%RH | 10 | |

Hardness, shore A | 50±5 | |

Thermal conductive rate, W/m.K | 0.25 | |

Working Temperature, ℃ | -60~100 | |

MAX Temperature, Short time, ℃ | 115 | |

Chapu 6857 flame retardant 5:1 room temperature or heating temperature Polyurethane encapsulation

Two-component solvent-free potting resin. It cures in room temperature or heating temperature. It’s using for electronics sealing, potting, flame resistant etc. The raw material does not contain heavy metal, it’s environmental with widely operability, high physical properties of the finished product, good adhesion with substrates. It can be deep cured, less heat release when curing, low shrinkage rate. Excellent flexibility after curing with flame retardant efficiency. It is used for pouring and potting of communication equipment, transformers, control power supplies, ignition controllers, electronic sensors, etc.

Excellent low temperature and weather resistance properties.

Excellent flame retardant

Excellent electrical insulation

Excellent flame retardancy

Good waterproof, moisture resistance, very low water absorption

Good adhesion to almost metal and plastic.

Color: Black

Packaging:Part A-25kg/Bucket, Part B-5kg/Bucket

Application: It is used for pouring and potting of communication equipment, transformers, control power supplies, ignition controllers, electronic sensors, etc.

PROPERTY | STANDARD/UNITS | VALUE of 6857 | |

—- | —- | PART A | PART B |

Appearance | Visual inspection | Black liquid | Brown liquid |

Viscosity | 25°C, cps | 800±100 | 200±40 |

Density | 25°C, g/cm3 | 0.95±0.05 | 1.15±0.05 |

Pot life | 25°C, min | 35~45 (till 10,000 cps) | |

Mixture ratio | Mass ratio | A:B=4: 3 | |

Mixture viscosity | 25°C, cps | 450±100 | |

Initial curing time | 25°C, hour | 8~10 | |

Hardness | Shore A | 35±5 | |

Working temperature | °C | -40~100 | |

Thermal conductivity | W/m.K | 0.25 | |

Chapu 6066 two-component no solvent RTV/Heating curing Polyurethane Potting Sealant

Two-component no solvent RTV/Heating curing resin elastomer compound. Used for two component sealing, filling, fire retardant and thermal conductive area. Raw materials are free of heavy metal, green and environmental protection, wide technology operability. Finished products are with high physical properties, good adhesion to the substrate.

Low viscosity, easy to operation

Excellent performance on low-temperature and weatherability

Excellent electrical insulativity and stability

Good waterproof, moisture resistance, very low water absorption

Good adhesion to most metals and plastics

Color: Black

Packaging:Part A-25kg/Bucket, Part B-5kg/Bucket

Application: For casting and potting of communications equipment, transformers, electronic instruments panel components, electronic ignition controllers, electronic sensors, connectors etc

| PROPERTY | STANDARD/UNITS | VALUE of 6066 | |

| —- | —- | PART A | PART B |

| Appearance | Visual inspection | Beige liquid | Brown liquid |

| Viscosity | 25°C, cps | 5,500±500 | 150±50 |

| Density | 25°C, g/cm3 | 1.45±0.02 | 1.2±0.02 |

| Pot life | 25°C, min | 30~40 (till 5,000 cps) | |

| Mixture ratio | Mass ratio | A:B=5: 1 | |

| Curing time | 25°C, hour | 2 | |

| Hardness | Shore A | 85±5 | |

| Volume resistance | DC500V, ohm-cm | >1.0×1014 | |

| Working temperature | °C | -40~100 | |

| Thermal conductivity | W/m.K | 0.4 | |